Equipment & Features »

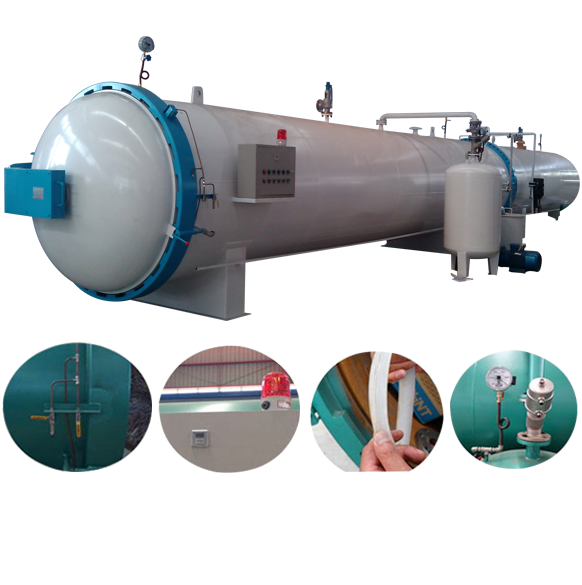

- Material of the equipment: Q345R steel which have good comprehensive mechanical property and processing property is a kind of pressure vessel special material.

- Welding method: Automatic submerged arc welding, it has advantages of high productivity, good weld quality and low labor intensity. And it also hasn’t arc radiation.

- The ways to open the door: Open door manually, open the door by electricity, open the door by hydraulic. Advanced open door method ,only one young girl can open the door easily.

- The sealing way: With the gas-filled silica gel seal ring, the air filled style sealing effect of the equipment is significantly better than others’. And the life of the equipment is more than one year.

- Safety interlocking methods of the door of the tank: Automatic pressure safety interlocking method and Manual safety interlocking method, it solved the safety problem of wrong operation.

- Automatic set time function and light alarm: It can save worker’s time ,you can set any time in the control box ,once it finish ,it will stop work and alarm.

- Quickly discharge chemical :10 minutes to discharge chemical ,improve treated time.

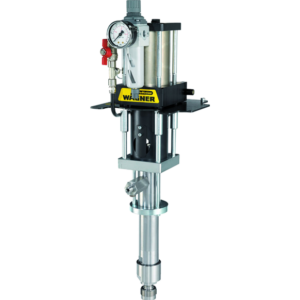

- Perfect control system: The system match automatic inlet and outlet air pneumatic valve, it can balance tank pressure well.

- High efficiency and save energy: once the equipment finish vacuum and pressure stage ,the pump will stop ,but whole tank still keep vacuum state.

- Level control: With magnetic level gauge, when the tank preservative added to the specified location, close the valve to stop preservatives enter.

- Vacuum control: Setting a negative pressure meter, vacuum reaches a predetermined value, close the valve to stop the vacuum.

- Pressure Control: Design two pressure gauges, Through the valve control the tank pressure, when reaches a predetermined pressure close the valve, stop boost, and maintain a certain pressure time after pressure relief. Design 2 flange open safety valve, after reaching the design pressure relief valve automatically opens, ensure the safety of the tank.

With Machine (Free) »

- Installation & Training

- 1 year servicing

- Toolkit & Manual

Reviews

There are no reviews yet.