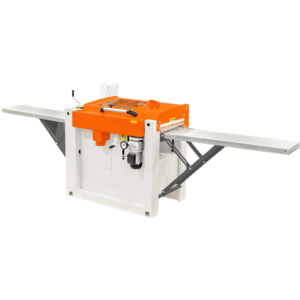

Four Sided Moulder MP260

Whether you are a woodworker, farmer or timber company needing additional capacity, the MP260 is a versatile Four-sided Moulder & Planer that is able to convert rough-sawn timber into finished planed and moulded boards. Multiple planing and profile knives can be combined to produce various 4-sided planed and moulded timber in only one pass through the MP260.

Specification:

CAPACITY

4-sided moulding Max. Width: 260 mm Height: 10 - 100 mm 2-sided moulding Max. Width: 300 mm Height: 10 - 230 mm 1-sided moulding or thicknessing Max. Width: 410 mm Height: 230 mmUPPER HORIZONTAL CUTTER

Diameter: 72 mm Width: 410 mm Power: (4 HP) Speed 6000 rpm: Max. Cutting Depth: 8 mm Max. Profile Depth: 20 mmLOWER HORIZONTAL CUTTER

Diameter: 72 mm Width: 300 mm Power: (4 HP) Speed 6000: rpm Cutting depth: 0 - 4 mm Max. Profile depth: 15 mmVERTICAL CUTTERS

Spindle diameter: 30 mm Max. Cutter Height: 100 mm Max. Diameter: 140 mm Power:(4 HP) Rotation Speed: 6000 rpm Max. Cutting Depth approx: 30 mmSTANDARD CUTTERS INCLUDED

Type TB90 steel fzb Diameter head: 90 mm Height head: 40 mm Blades type HSS Blades width: 50 mmPOWER FEED

Power: 0.37 kW Feed Speed: 2 - 12 m/minELECTRICAL

Total Power:16.5 HP Connection:: 3-phase, 16 A, 400-415 V or 230V (Available also in 1-phase)Four Sided Moulder MP360

For higher production levels in your workshop or woodworking business, the MP360 is a proven and versatile four-sided Moulder/Planer that is able to convert rough-sawn timber into finished planed and moulded boards, with higher hourly production levels and larger timber capacities. Multiple planing and profile knives can be combined to produce various 4-sided planed and moulded timber in only one pass through the MP360.

Specification:

CAPACITY

4-sided/planing moulding Max. Width: 350 mm Height: 10 - 160 mm 2-sided moulding Planing Width: 410 mm Height Range: 10 - 230 mm 1-sided Planing Max. Width: 510 mm Height: 230 mmUPPER HORIZONTAL CUTTER

Diameter: 88 mm Width: 510 mm Power: 7.5 HP Speed: 6000 rpm Max. Cutting Depth: 8 mm Max. Profile Depth: 20 mmLOWER HORIZONTAL CUTTER

Diameter: 72 mm Width: 410 mm Power: 7.5 HP Speed 6000: rpm Max. Cutting depth: 8 mm Max. Profile depth: 20 mmLOWER HORIZONTAL CUTTER

Diameter: 72 mm Width: 410 mm Power: 7.5 HP Rotation Speed: 6000 rpm Cutting Depth: 0 - 8 mm Profile Depth max: 10 mm (slot drill 15 mm)VERTICAL CUTTERS

Spindle diameter: 30 mm Max. Cutter Height: 130 mm Max. Diameter: 160 mm Power:(4 HP) Rotation Speed: 6000 rpm Max. Cutting Depth approx: 30 mmSTANDARD CUTTERS INCLUDED

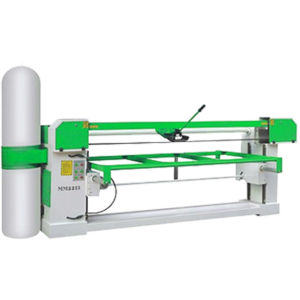

Type TB90 steel fzb Diameter head: TB 90 Steel mm Height head: 90 mm Blades Height: 40 mm Cut type plate HSS Cutting width: 50 mmHigh Frequency Curved Plywood Press YX150-SA

Specification:

Total hydraulic pressure: 150 ton Vertical hydraulic pressure: 150 ton Quantity of hydraulic cylinders: 2 pieces Working size: 2500*1300 mm Opening between up and down platen: 1100 mm Hydraulic cylinder stroke: 600 mm Hydraulic system rated pressure: 25 Mpa Overall size (L*W*H): 3300*1300*2200 mm Power: 380V, 3Phase, 220V,1Phase,50hz Total power for whole machine is 47.5kvaSpecification High Frequency Generator

Input Power: 40 KVA Output Power: 30 KW HF Output: 2 output Oscillation: 6.78 Mhz Protection: Overload protection, wind cooling pressure detection, filament 2 stages stars, lose phase protection Tuning Mode Variable capacitor Cooling Mode Force wind cooling Overall Size (L*W*H) 1050*950*1950 mm Power: 380V, 3 phase, 220V, 1 phase, 50hzHigh Frequency Edge Gluer SP20-SA

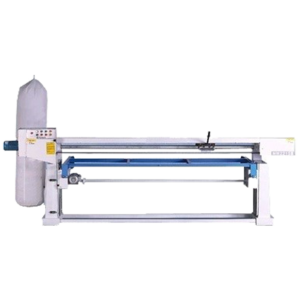

Specification:

OUTPUT POWER: 20KW CAPACITY LENGTH: 2440 mm WIDTH: 1220 mm THICKNESS: 8-100 mm PRESSING DIRECTION: Two Ways SIDE PRESSURE: 36 Ton(12 pcs of hydraulic cylinders) TOP PRESSURE: 9 Ton (3 pcs of hydraulic cylinders) OVERALL SIZE Press:L2700*W2150*H2100 mm Inlet:L3500*W1600*H800 mm Outlet:L2000*W1330*H800 mm HF Generator:L1000*W800*H1800 mm INPUT POWER: 3 Phase,380V,50Hz-30KVAHigh Frequency Vacuum Wood Dryer

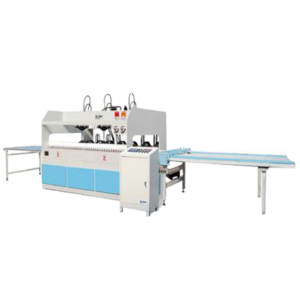

High frequency vacuum wood dryer is small but fast with low temperature drying machine, suitable for drying all kinds of wood, from veneer/lamella/wood board to thick lumber, even heavy timber. For thin pieces like veneer or floor lamella, HF vacuum drying not only offer short cycle solution but also eliminate curved or shrink problem. For thick and hard wood, HF vacuum drying brings good quality with uniform humidity, free of split or spark both on surface or inside, short drying cycle will help a lot to meet demand for production.