Equipment & Features »

- The thick steel sheet is sheared by plasma device.

- All the metal plate is done by the High-class laser cutting machine; which can ensure the precision and the final appearance.

- The main body has been done the quench treatment, to avoid the deformation during the processing or painting.

- The main parts have been done the vibration aging, to remove the internal stress, so can ensure the stability and the precision.

- All the body frame and metal plates have been done as powder coating process, to achieve the perfect appearance.

- The main parts have been done the processing on the high precision gantry milling center, to ensure the high levelness.

- All the main parts have been done the inspection on the coordinate measuring machine.

- Press Beam structure: Adopts high-class aluminum profile type press beam; The elevating is controlled on the touch screen via pushing button; with mechanical numerical gauge.

- Pre-heating unit:This unit can do the pre-heating on the edge of the board, to ensure the sealing performance. Especially for the area with high moisture and low temperature.

- Tape pressing structure:This machine adopts the six rolls tape pressing structure, the drive roll diameter will be Ø100mm, comes with 5 pcs driven rolls, to achieve the stable attaching of board and tape.

- Gluing structure:This edge bander adopts updraft type gluing structure, it is suitable to process the EVA type hot melt glue.

- End Cutting device (snapping device):Adopts single linear guide way structure with 45º Two pcs high speed motor with two cutting saw blades.

- Fine trimming device:Two pcs high-speed air-cooling spindle

Spindle angle is adjustable;Trimming amount is adjusted via pneumatic device, which will clamp the tape with the same thickness;Come with the individual exhaust inlet - Scrapping device:Come with air jet, which can blow the small chips;

Scrapping is adjustable through pneumatic device, with linear guide way structure. - Buffing unit:Adopts the cotton wheels to polishing on the sealed edge; Which can improve the scrapping appearance, also can clean some glue thread on surface.

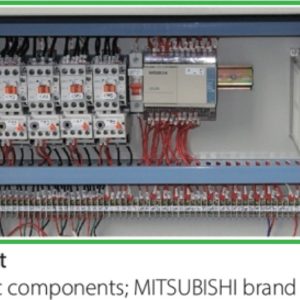

- Electric components: Input voltage 380V. Individual inverter control, come with motor braking with phase sequence protection device.

- Control system: All the functions is controlled via PLC control system; HMI is 7inch touch screen; Come with individual temperature controller, to ensure the stability of the system.

With Machine (Free) »

- Installation & Training

- 1 year servicing

- Tool Box

Reviews

There are no reviews yet.