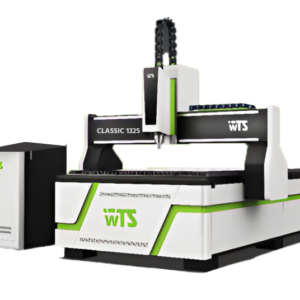

CNC ROUTER WTS CLASSIC (DSP)

Technical Parameters :

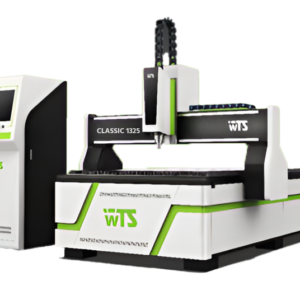

Travelling Size : 2500*1300*300 mm Control System : Richauto A11E Spindle : HQD, 6 KW, 18000 rpm, Air Cooling Inverter : Fuling 7.5 KW Power : 220V, 50 hz, Single Phase X, Y Axis Driving : AC Servo Motor Yako 750W Z Axis Driving : AC Servo Motor Yako 750W with Brake X, Y Transmission System : Rack & Pinion 1.5m Z Transmission System : Ball Screw With Coupling Structure Linear Guide Way And Block : 25mm Electric Components : Schneider Sensors : Omron, Japan Table Height : Standard Working Table Structure : T- Slot Aluminium Table And Hard White PVC Pasted On Top Control Cabinet : Independent Lubrication System : Manual Body Structure : Steel Tube Structure With 6 LegsCNC ROUTER WTS CLASSIC (NC)

Technical Parameters :

Travelling Size : 2500*1300*300 mm Control System : Lamda NC Spindle : HQD, 6 KW, 18000 rpm, Air Cooling Inverter : Fuling 7.5 KW Power : 220V, 50 hz, Single Phase X, Y Axis Driving : AC Servo Motor Yako 750W Z Axis Driving : AC Servo Motor Yako 750W with Brake X, Y Transmission System : Rack & Pinion 1.5m Z Transmission System : Ball Screw With Coupling Structure Linear Guide Way And Block : 25mm Electric Components : Schneider Sensors : Omron, Japan Table Height : Standard Working Table Structure : T- Slot Aluminium Table And Hard White PVC Pasted On Top Control Cabinet : Independent Lubrication System : Manual Body Structure : Steel Tube Structure With 6 LegsCNC ROUTER WTS COMPACT 1325

Technical Parameters :

Travelling Size : 2500*1300*300 mm Control System : DSP A11 Spindle : HQD, 6 KW, Air Cooling Inverter : Best 7.5 KW Power : 220V, 50 hz, Single Phase Motor : DVS 750W AC servo motor Drive : DVS 750W AC servo motor X, Y Transmission System : High precision rack and speed reducer for XY-axis Z Transmission System : TBI Ball Screw with Coupling Structure Linear Guide Way And Block : 25mm Hiwin guide rail Electric Components : Schneider Sensors : Omron, Japan Table Height : Standard Working Table Structure : T- Slot Work Table Control Cabinet : Independent Lubrication System : ManualCNC ROUTER WTS COMPACT 1425

Technical Parameters :

Travelling Size : 2500*1400*300 mm Control System : DSP A11 Spindle : HQD, 6 KW, Air Cooling Inverter : Best 7.5 KW Power : 220V, 50 hz, Single Phase Motor : DVS 750W AC servo motor Drive : DVS 750W AC servo motor X, Y Transmission System : High precision rack and speed reducer for XY-axis Z Transmission System : TBI Ball Screw with Coupling Structure Linear Guide Way And Block : 25mm Hiwin guide rail Electric Components : Schneider Sensors : Omron, Japan Table Height : Standard Working Table Structure : T- Slot Work Table Control Cabinet : Independent Lubrication System : ManualCNC ROUTER WTS RACER PRO (DSP)

Technical Parameters :

Travelling Size : 2500*1300*300 mm Control System : RichAuto A11E Spindle : HQD, 6 KW, 18000 rpm, Air Cooling Inverter : Best 7.5 KW Power : 220V,50HZ,Single Phase X, Y Axis Driving : Yako Easy Servo Motor and Driver Z Axis Driving : Yako Easy Servo Motor and Driver X, Y Transmission System : Rack And Pinion 1.5m Z Transmission System : Ball Screw With Coupling Structure Linear Guide Way And Block : 25mm Electric Components : Schneider Sensors : Omron, Japan Table Height : Standard Working Table Structure : T-slot table + White PVC (Pasted on the aluminium table) Control Cabinet : Independent Lubrication System : Manual Body Structure : Steel Tube Structure With 6 LegsCNC ROUTER WTS RACER PRO (NC)

Technical Parameters :

Travelling Size : 2500*1300*300 mm Control System : NC Spindle : HQD, 6 KW, 18000 rpm, Air Cooling Inverter : Best 7.5 KW Power : 220V, 50 hz, Single Phase X, Y Axis Driving : Yako Easy Servo Motor and Drive Z Axis Driving : Yako Easy Servo Motor and Drive X, Y Transmission System : Rack And Pinion 1.5m Z Transmission System : Ball Screw With Coupling Structure Linear Guide Way And Block : 25mm Electric Components : Schneider Sensors : Omron, Japan Table Height : Standard Working Table Structure : T-slot table + White PVC (Pasted on the aluminium table) Control Cabinet : Independent Lubrication System : Manual Body Structure : Steel Tube Structure With 6 LegsCNC ROUTER WTS THUNDER

Technical Parameters :

Travelling Size : 2500*1300*300 mm Control System : Richauto DSP A11 Spindle : HQD, 6 KW, 24000 rpm, Air Cooling Inverter : Fulling 7.5 KW Power : 220V, 50 hz, Single Phase Motor : Leadshine 750W servo motor Drive : Leadshine 750W servo drive Z Transmission System : Taiwan 2505 TBI ball screw on Z axis Linear Guide Way And Block : Taiwan HIWIN 25mm square rails & 1.5M Helical rack Electric Components : Schneider Sensors : Omron, Japan Table Height : Standard Working Table Structure : Aluminum profile table+T slots,with PVC Lubrication System : Auto lubricationUnlocking Precision and Efficiency: Wood Tech Solution’s CNC Router Machines

In the realm of modern woodworking, precision and efficiency reign supreme. At Wood Tech Solution, we understand the pivotal role that technology plays in elevating craftsmanship to new heights. Enter the CNC router machines – a game-changer in the woodworking industry.

What is a CNC Router Machine?

A CNC is a computer-controlled cutting device that translates digital designs into precise, automated movements. It operates on a Cartesian coordinate system, where the cutting tool follows instructions from computer software to carve intricate patterns, shapes, and designs into various materials, including wood, plastic, and metal.

The Unmatched Utility of CNC Router Machines

The utility of CNC machines transcends traditional woodworking methods. With unparalleled precision and repeatability, these machines empower craftsmen to unleash their creativity without constraints. Whether it’s crafting intricate furniture pieces, architectural embellishments, or personalized signage, machines offer unmatched versatility and efficiency.

Why Choose CNC Router Machines?

The decision to embrace CNC technology is not just a leap forward; it’s a strategic imperative for any woodworking enthusiast or professional. By leveraging this machines, craftsmen can:

- Boost Productivity: Say goodbye to manual labor-intensive tasks. The machines streamline production processes, allowing for faster turnaround times and increased output.

- Ensure Precision: Every cut is executed with pinpoint accuracy, eliminating the margin for error inherent in manual woodworking techniques. This precision translates to impeccable craftsmanship and satisfied clients.

- Expand Creative Horizons: With the ability to effortlessly execute complex designs, CNC router machines embolden artisans to explore new design possibilities and push the boundaries of their craft.

Understanding CNC Router Machine Prices-

When considering the purchase of a CNC router machine, it’s essential to understand the factors that influence pricing. Here are some key aspects that affect the cost:

-

- Machine Size and Capabilities: Larger machines with advanced features and higher precision tend to be more expensive. Consider your specific needs to determine the right balance between size and cost.

- Quality of Parts: There are many variations of parts in this industry. Machine prices vary greatly based on the origin and quality of parts. You will be surprised to know that machine price difference can be lakhs of rupees based only on machine rail guide. beside this, there are many other parts of the machine like fake spindle, poor quality electronics parts, and even depending on the thickness of the machine body, the price of the machine can vary. Many low category factories have been established in China who are offering these low category machines at low prices in Bangladesh. The point of concern is that many of the machines in Bangladesh are being cheated by buying such low quality machines. For that reason, before buying the CNC router machine, you should check it well and then buy the machine.

- Motor Power and Speed: Machines with more powerful motors and higher operating speeds are typically priced higher, as they can handle more demanding tasks and offer faster production times.

- Build Quality and Materials: The construction and materials used in the machine’s build significantly impact its durability and performance. High-quality machines built with robust materials may come at a higher price but offer long-term reliability.

- Additional Features: Advanced features such as automatic tool changers, vacuum tables, and dust collection systems can add to the overall cost but enhance the machine’s functionality and ease of use.

Affordable CNC Router Machines for Every Budget-

At Wood Tech Solution, we believe that quality CNC router machines should be accessible to everyone. Our range includes models at various price points to ensure that you find the perfect match for your budget.

Why Choose Wood Tech Solution?

When it comes to investing in a CNC router machine, discerning craftsmen demand nothing but the best. At Wood Tech Solution, we take immense pride in being the premier destination for top-of-the-line. Here’s why our customers trust us:

- Unrivaled Expertise: With years of industry experience and technical know-how, we understand the unique needs and challenges of woodworking professionals.

- Cutting-Edge Technology: Our CNC machines are crafted using state-of-the-art technology and premium-grade materials, ensuring unmatched precision and longevity.

- Dedicated Support: From installation and training to ongoing technical support, our team is committed to providing comprehensive assistance every step of the way.

Experience Excellence with Wood Tech Solution

At Wood Tech Solution, we are committed to providing our customers with the best CNC router machines at competitive prices. Whether you’re looking for an affordable entry-level machine or a high-end industrial model, we have the perfect solution to meet your needs. Explore our extensive range of CNC routers today and discover why we are the preferred choice for woodworkers and manufacturers alike.

For more information or to browse our selection, visit our website or contact our sales team. Wood Tech Solution – your partner in precision and performance.