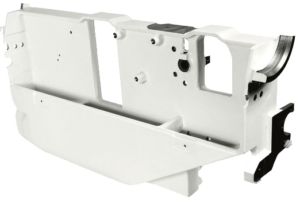

Saw unit: a perfect cut. Maxim um torsional rigidity and the total absence of vibration through the closed loop structure of the saw unit which ensures perfect alignment of the blades during tilted and difficult cuts.

um torsional rigidity and the total absence of vibration through the closed loop structure of the saw unit which ensures perfect alignment of the blades during tilted and difficult cuts.

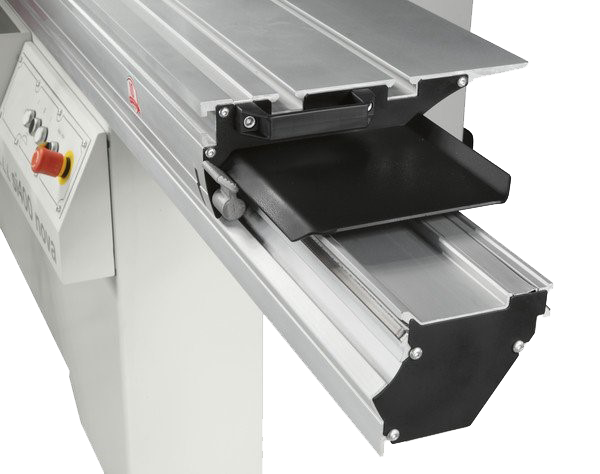

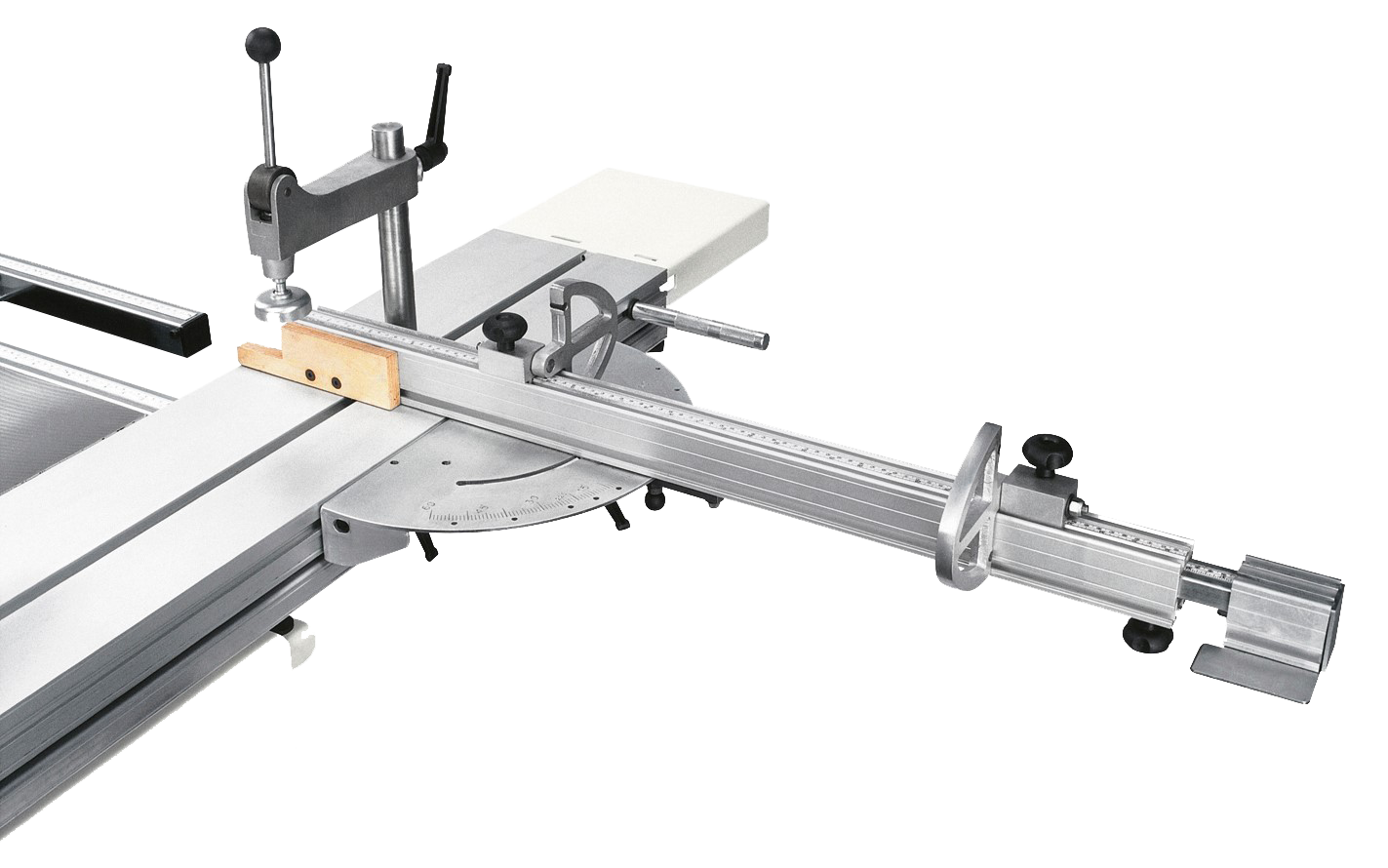

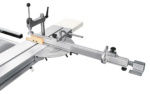

Sliding carriage:  smooth sliding and a solid work surface. The wide section of the carriage, with closed reticular geometry provides extreme rigidity and minimum deflection. A smooth operating motion is guaranteed over time by the system of sliding bearings running on hardened steel guides using an exclusive method of mechanical fixing

smooth sliding and a solid work surface. The wide section of the carriage, with closed reticular geometry provides extreme rigidity and minimum deflection. A smooth operating motion is guaranteed over time by the system of sliding bearings running on hardened steel guides using an exclusive method of mechanical fixing

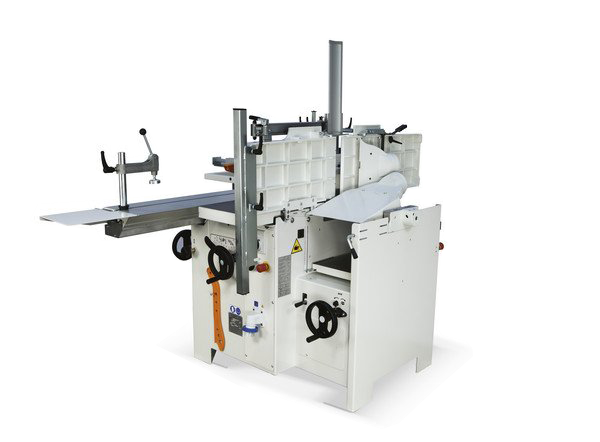

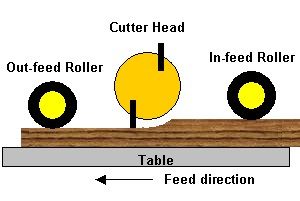

Higher efficiency During the changeover from surfacing to thicknessing the surfacing tables open towards the inside of the machine with a 90° angle, facilitating thicknessing. Work pieces with a maximum height of 220 mm can be machined to the thicknesser. The new design of the dust-conveyor, protecting the cutter block, is specifically intended to further increase system safety and efficiency.

During the changeover from surfacing to thicknessing the surfacing tables open towards the inside of the machine with a 90° angle, facilitating thicknessing. Work pieces with a maximum height of 220 mm can be machined to the thicknesser. The new design of the dust-conveyor, protecting the cutter block, is specifically intended to further increase system safety and efficiency.

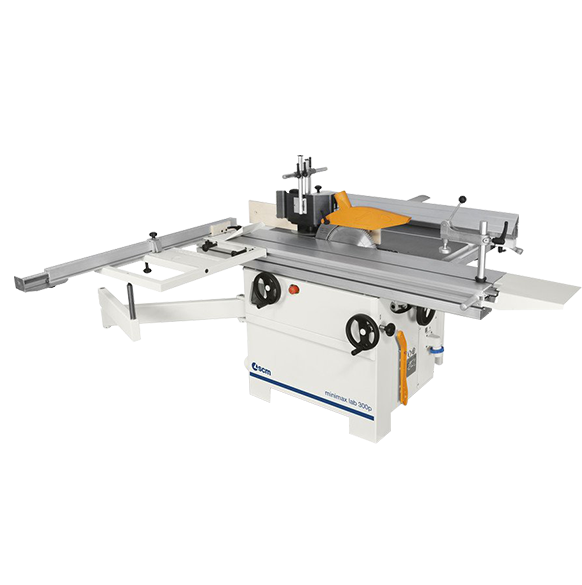

Superior performance The spindle moulder unit has a spindle with a useful working length of 100 mm. A tool with a maximum diameter of 180 mm can be retracted under the worktable. For machine maximum safety and increased flexibility, a spindle moulder protective hood for shaping is supplied as standard.

The spindle moulder unit has a spindle with a useful working length of 100 mm. A tool with a maximum diameter of 180 mm can be retracted under the worktable. For machine maximum safety and increased flexibility, a spindle moulder protective hood for shaping is supplied as standard.

Equipment & Features »

- Versatile and compact universal combined machine with the more advanced technological solutions for precision, reliability and safety.

- 6hp motors, 2-speed shaper, 3-knife Terse cutter head. 12″ saw blade with independently adjustable scoring

- 5.5′ sliding table allows user to crosscut 4×8 panels square and efficiently.

With Machine (Free) »

- Installation & Training

- 1 year servicing

- Toolkit & Manual

Origin »

- Italy

Reviews

There are no reviews yet.